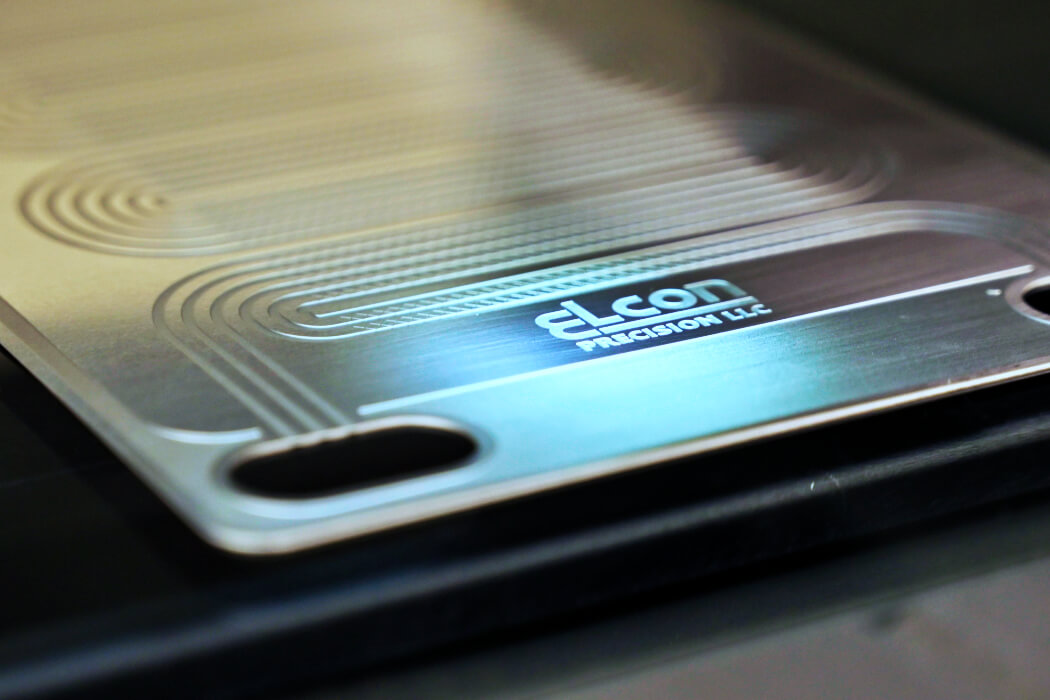

Our Photochemical Etching Capabilities

Elcon Precision provides Invar etching services with benefits that enhance your application. You can expect the following benefits when you choose to work with:

- High process control, guaranteeing parts that meet your specifications

- Fast turnaround and etching time

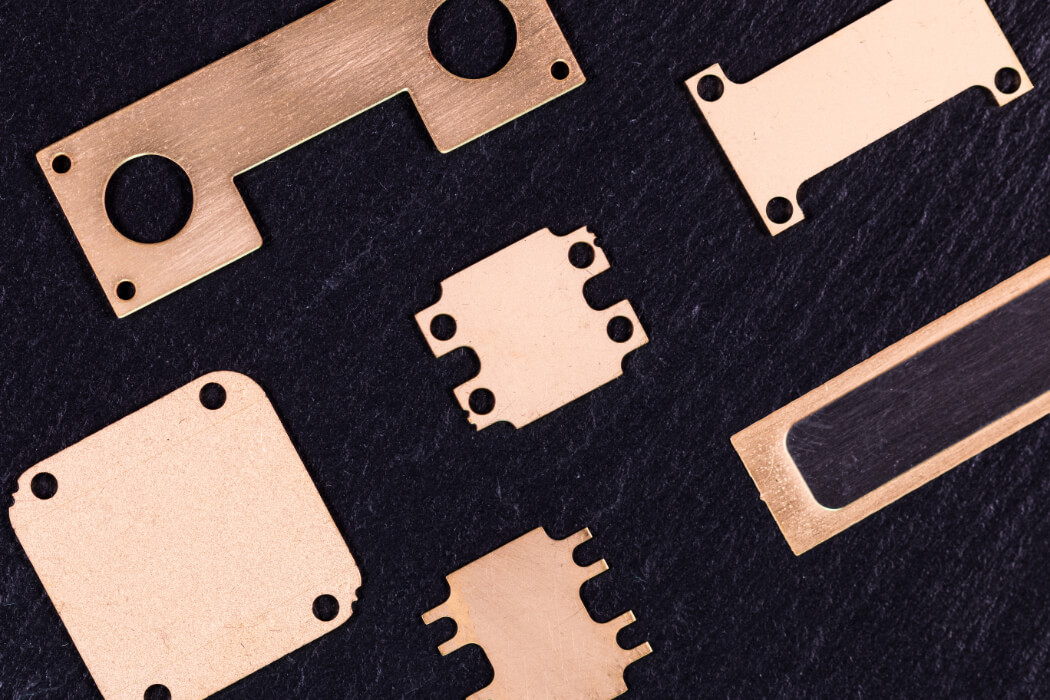

- Stress-free, burr-free precision parts that are ideal for post assemblies or stacking

- Low-cost tooling

- Design flexibility with digital tooling = increased complexity, with no incremental cost

- Dimensional repeatability

- Precise and complex geometries

- 3D photo etching (check out our control grids etching capabilities)

- Knife and needle edges

- Micromachining

- Step and half etching

- Selective plating and thin films

- 0.0005 in. to 0.100 in material thickness

When you submit your design to us, we’ll uphold the highest quality of customer satisfaction to get your product finished right.

Invar Applications

Invar is used in several different industries and applications. These include:

- RF systems

- MRI and imaging equipment

- Antenna systems

- Semiconductor equipment

- Microelectromechanical systems (MEMS)

- Automotive sensors

Industries That Use Invar Etching

Invar etching is used heavily in the following industries:

- Solar

- Military

- Telecommunications

- Electronics