What Are Electron Guns?

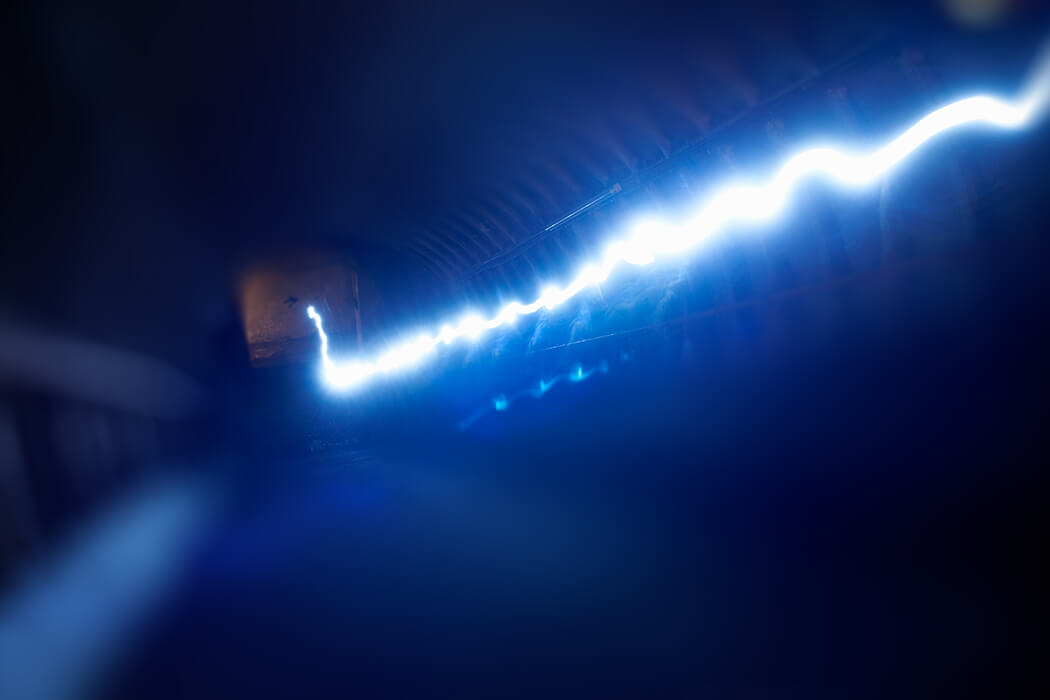

Also known as an electron cannon or electron generator, an electron gun is a specialized device that produces a controlled, focused beam of electrons for use in high-tech systems. Electric field generation is fundamental to the operation of electron guns, enabling the acceleration and focusing of electrons. Within the electron gun, an electron emitter or electron source produces or emits electrons through specific emission mechanisms such as thermionic emission or field emission. The emission mechanism depends on overcoming the work function and energy barrier of the emitter material, which determines how electrons are generated and emitted. The type of electron source and emission mechanism can be tailored to produce electron beams for different applications, such as electron microscopes that reveal atomic-level detail to semiconductor manufacturing equipment used in microchip production. They also power cathode ray tubes (CRTs), defense and aerospace instruments, and medical imaging systems such as X-ray and CT scanners.

At their core, electron guns require exceptional vacuum integrity, high-voltage insulation, and thermal stability, performance demands that depend on the quality of the precision components inside. Robust vacuum systems are crucial for maintaining ultra-high vacuum conditions, which prevent contamination and ensure reliable operation.

Things to Consider About Electron Beam Characteristics

The performance of any electron gun, whether it’s an electron cannon for materials analysis or an electron generator for imaging, is defined by the quality and control of the electron beam it produces. Precision in beam design enables advanced applications across science, manufacturing, and defense.

Here are the key factors that determine beam performance:

Energy and Acceleration: The kinetic energy of electrons is set by the voltage between the cathode and anode. The anode accelerates electrons by applying a high voltage, increasing their energy as they move toward the target. By adjusting this potential difference, engineers can fine-tune beam energy for specific tasks, from high-resolution microscopy to surface modification. Electrons must have sufficient energy to achieve effective ionization or imaging, depending on the application.

Beam Current and Stability: Beam current, or the number of electrons emitted per second, is controlled by the emission current of the cathode. Stable, consistent current ensures reliable results in imaging, lithography, and analytical systems.

More Key Factors

Energy Spread and Resolution: A narrower range of electron energies leads to sharper images and more precise measurements. Field-emission sources typically achieve a tighter energy spread than thermionic emitters, making them ideal for high-resolution applications. The Schottky effect, which lowers the surface barrier under high electric fields, enhances electron emission and provides stable high-current sources.

Beam Control and Focus: Electric and magnetic fields are used to steer and focus the beam with precision. Electric fields, created by voltages applied to electrodes and lenses, are essential for focusing, aligning, and correcting beam aberrations. Components like the Wehnelt cylinder help refine focus and intensity, while magnetic lenses allow for pinpoint targeting of specific areas. The Wehnelt cylinder contains a hole or aperture that shapes and directs the electron flow, ensuring the beam is properly formed.

Material selection

Material selection for the emitter is equally important. Advanced materials such as lanthanum hexaboride (LaB₆) deliver high-brightness beams with minimal energy spread, while robust vacuum environments protect the emitter from contamination and ensure consistent long-term operation. The emitter is typically heated to produce electrons via thermionic emission, and heating methods and temperature control are critical for stable emission. Heating the cathode or filament (such as tungsten or LaB₆) enables efficient electron release, and feedback control systems may regulate the temperature to maintain emission stability. Direct current is often used in laser-driven polarized electron guns to generate tightly focused, high-energy electron beams.

The flow and stream of electrons are controlled by electrodes and grids to ensure a stable, continuous electron beam. The electron gun generates a stream of electrons that is directed at the target for imaging or analysis.

By carefully balancing these parameters, engineers can design electron guns that generate beams tailored to their application, whether it’s producing atomic-scale images, enabling precise spectroscopic analysis, or driving high-performance manufacturing processes.

Elcon Precision’s Role in Electron Gun Performance

For over five decades, Elcon Precision has been a trusted partner to engineers and OEMs designing and manufacturing electron guns, electron cannons, and electron generators. Our expertise lies in producing the high-performance components that make these systems more durable, stable, and precise, even in the most demanding environments.

Our capabilities include:

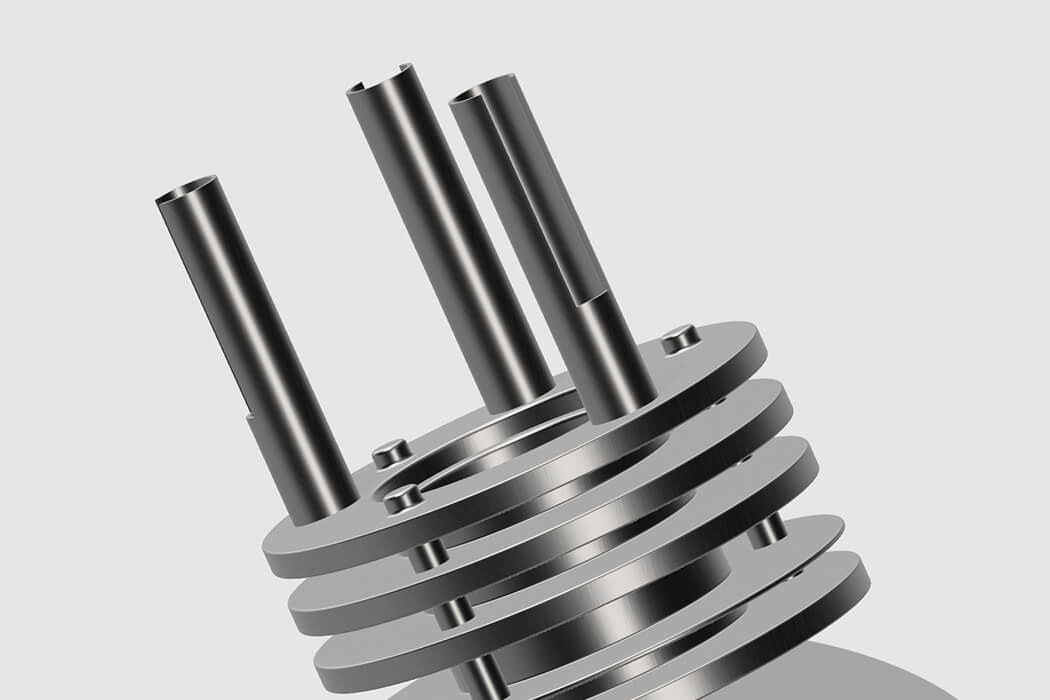

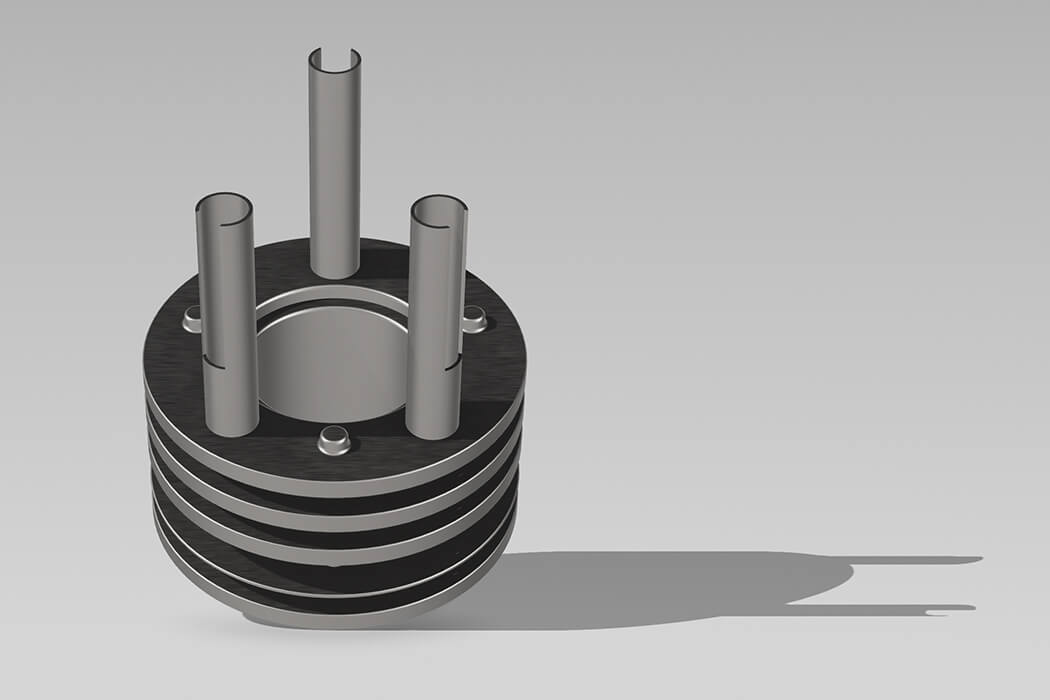

- Ceramic-to-Metal Seals: Hermetically sealed interfaces that ensure vacuum integrity and high-voltage insulation.

- Brazed Assemblies: High-strength, precision-bonded structures that withstand extreme thermal and electrical stress.

- Cathode Supports & Housings: Precision-engineered components designed to maintain alignment and electron beam focus.

- Custom Components: Tailored solutions for unique electron gun architectures and performance requirements.

Our precision components enable accurate measurement of beam currents and current density per unit area, supporting applications that require uniform and stable electron beams.

Every component we deliver is built to exacting specifications, enabling optimal electron beam generation and long-term reliability, and helping achieve consistent performance and precise control over electron gun operation.

Why Choose Elcon Precision for Your Electron Gun Components?

Partnering with Elcon means more than sourcing parts, it means collaborating with a team deeply invested in the success of your project.

- Reliability in Extreme Environments: Our ceramic-to-metal seals and brazed assemblies maintain performance under ultra-high vacuum, high voltage, and elevated temperature conditions.

- Proven Expertise: With 50+ years of experience supporting critical technologies, Elcon is a trusted name across scientific, industrial, and defense sectors, collaborating closely with graduate students and research institutions to develop advanced electron gun technologies.

- Design Flexibility: Whether scaling production or developing one-of-a-kind assemblies, we customize components to meet your exact specifications, including solutions for rapidly switching electron gun systems.

- Quality You Can Trust: ISO-certified processes, complete traceability, and rigorous testing ensure consistent performance and reliability.

Applications & Industries

Elcon Precision components power some of the world’s most advanced electron guns and related technologies, supporting the analysis of particles and ions in research and industrial applications. Our solutions are trusted in applications such as:

- Scientific Research & Electron Microscopy: Delivering stable beams for atomic-resolution imaging, achieving small spot sizes down to a few microns for high-resolution analysis. Faraday cups are used for precise measurement of emitted electrons and beam currents. Accurate measurement and analysis often require samples to be placed in close proximity to standards or detectors to ensure high measurement accuracy and reduce variability.

- Semiconductor & Materials Processing: Supporting precision lithography, etching, and deposition tools by targeting specific areas with high electron energy and controlling the axis of the electron beam for optimal results.

- Aerospace & Defense: Enabling mission-critical electron cannons, high-energy systems, and the use of ion beams and charged particles in advanced defense applications.

- Medical Imaging: Powering X-ray tubes, CT scanners, and diagnostic instruments with reliable electron generation, utilizing light emission and the photoelectric effect in X-ray production.

Partner with Elcon Precision for Your Next Electron Gun Project

From custom electron generator components to complete assemblies, Elcon Precision is ready to support your next innovation. Our engineering team collaborates closely with you to design, prototype, and deliver solutions that meet your performance goals, on time and on budget.