The Photonics Industry

Photonics is the science and engineering of generating, directing, and detecting light for applications in communication, sensing, imaging, and energy transfer. Technologies such as fiber-optic communication, LiDAR, laser-based instrumentation, semiconductor photonics, and quantum systems depend on precise optical alignment and stable mechanical interfaces.

These systems frequently combine ceramic and metal components—each with different thermal and mechanical characteristics. Reliable performance requires joining methods and packaging approaches that maintain alignment, ensure electrical isolation, and protect sensitive optical elements from contamination.

This intersection of light-based functionality and advanced material interfaces is where Elcon Precision’s manufacturing capabilities are most relevant.

The Engineering Challenge

High-performance photonic assemblies must withstand wide thermal swings, vibration, vacuum environments, and long operational lifetimes. Small deviations in material performance, outgassing, or mechanical stability can disrupt beam paths, shift focus, or degrade sensor sensitivity.

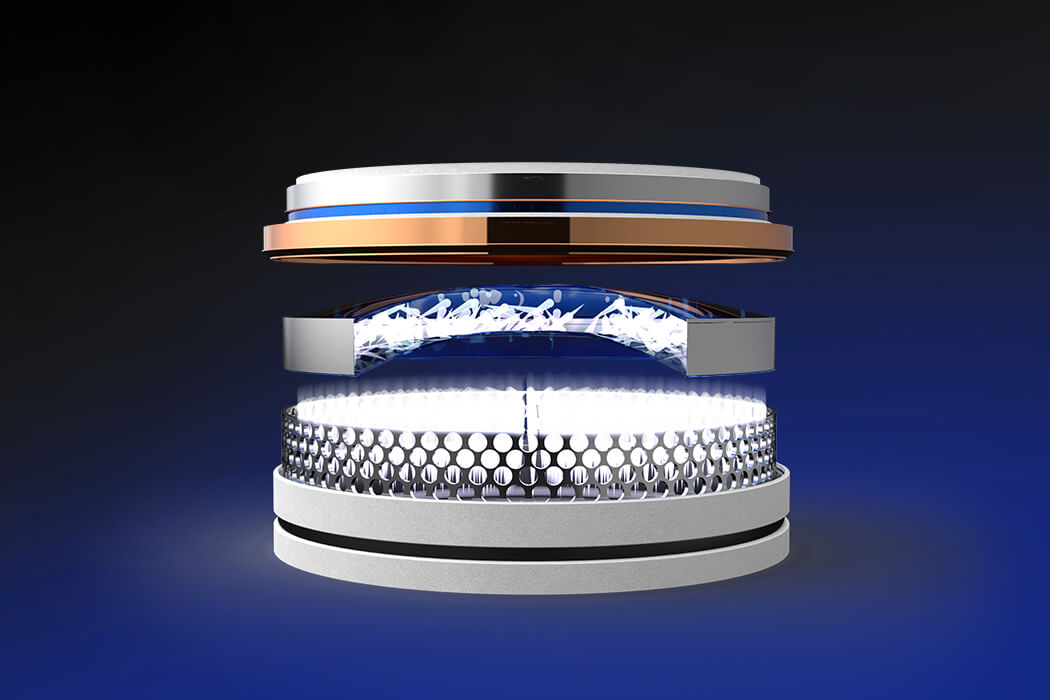

Because optical and optoelectronic components often rely on mixed-material interfaces, precision brazing and hermetic sealing are critical. These processes:

- Provide stable alignment for optics, detectors, and fiber-coupled elements

- Preserve vacuum integrity and protect against moisture and particulates

- Create robust interfaces between dissimilar materials without inducing stress

- Maintain electrical isolation while supporting high-voltage or high-power operation

For many photonics OEMs, the reliability of these joints and packages directly influences system accuracy and lifetime.

Photonic Integrated Circuits: Enabling Next-Generation Photonics

Photonic integrated circuits (PICs) are at the forefront of next-generation photonics, enabling the integration of multiple photonic components, such as lasers, modulators, and detectors, onto a single chip. This breakthrough allows for the creation of complex photonic circuits that can perform a wide range of functions, from high-speed optical communication to advanced sensing and imaging. By leveraging precision optics and advanced optical design, PICs are transforming industries including telecommunications, automotive, and healthcare, where the demand for rapid data transfer, reliable sensing, and high-resolution imaging is ever-increasing.

The fabrication of photonic integrated circuits draws on established semiconductor industry processes, such as photolithography and etching, to achieve high-volume production of precision optical components. Elcon’s approach not only ensures consistency and scalability but also enables the integration of diverse optical components and photonic elements within a compact footprint. As a result, PICs are driving the development of more efficient, compact, and versatile optical systems, paving the way for innovative solutions in communication, automotive safety, medical diagnostics, and beyond. Our ability to support the combination of complex photonic circuits on a single chip is accelerating the evolution of photonics technology and opening new possibilities for advanced applications across a broad range of industries.

Elcon’s Capabilities for Photonics

Elcon Precision manufactures components used in optical, laser, photonic, and optoelectronic assemblies where precision and hermeticity are essential.

Core capabilities include:

- Ceramic-to-metal hermetic assemblies for high-voltage, vacuum, and environmentally demanding systems

- Metallization and plating of ceramics and specialty materials, producing repeatable solderable or brazable surfaces

- Brazing of dissimilar materials (ceramic, glass, and multiple metal alloys) with controlled thermal processing

- Ultra-high-vacuum (UHV) and space-rated sealing, supporting low-outgassing and radiation-resistant applications

- Sub-micron precision, tight dimensional control, and repeatable alignment, achieved through in-house machining and inspection

- Photochemical machining, producing precise and repeatable components for demanding applications

Elcon’s vertically integrated approach minimizes variability and ensures consistency across every process step.

Typical Applications and Components

Elcon manufactures supporting components for photonics systems requiring mechanical stability, vacuum integrity, and precise alignment. Typical applications include:

- Laser and photodiode housings

- Fiber-optic feedthroughs and hermetic connectors

- Metallized and brazed sapphire windows and components

- Detector and sensor packages for imaging, spectroscopy, and scientific instrumentation

- Ceramic and metal optical mounts, headers, and vacuum-sealed windows

- Interfaces for space-based or high-temperature optical systems

- Components for LiDAR, free-space communication, and optical instrumentation

- Photochemical-etched components, including optical encoders, apertures, beam splitters, masks & reticles, heat sinks, and filters

These assemblies serve optical engineers, system designers, and photonics OEMs seeking reliable, long-term performance in challenging environments.

Materials

Elcon works with material systems commonly required for photonics components:

Materials

- Sapphire

- Alumina ceramics

- Silicon nitride

- Kovar

- Tungsten

- Titanium

- Stainless steel

- Glass ceramics

Processes

Brazing Alloys

- Active brazes for ceramic and metal joining

- Passive brazes selected for joint strength and CTE compatibility

Metallization Systems

- Molybdenum/manganese

- Molybdenum/manganese/tungsten

All critical processes are performed in-house, ensuring consistency, optimized thermal paths, and stable electrical performance.

Why Elcon Precision Stands Out

Elcon Precision is one of the few U.S. manufacturers combining metallization, machining, brazing, ceramic-to-metal joining, and inspection within a single facility. This allows for complete control over assemblies that must remain stable in optical, vacuum, and high-voltage environments.

Advantages for photonics OEMs

- 50+ years of experience manufacturing high-reliability assemblies

- Proven manufacturing record in aerospace, defense, scientific instrumentation, and semiconductor-adjacent photonics

- End-to-end control, from material selection through sealing and inspection

- ITAR-compliant production for controlled or sensitive programs

Elcon’s expertise in material science and joining methods supports the long-term stability required for advanced photonics systems.on provides the material science expertise needed to stabilize complex assemblies.

Industry Outlook: The Future of Precision Manufacturing in Photonics and How Elcon Precision is on the Cutting Edge

The future of precision manufacturing in photonics is marked by rapid innovation and expanding opportunities across a range of industries. Advances in photonic integrated circuit technology and precision optics are enabling the creation of increasingly complex photonic circuits and precision optical components, driving new applications in automotive, healthcare, telecommunications, and beyond. The use of custom lenses, micro-optics, and high-performance sensors is becoming essential for advanced imaging and detection systems, particularly as autonomous vehicles and smart devices become more prevalent.

Emerging materials such as silicon dioxide and lithium niobate, along with novel fabrication techniques, are pushing the boundaries of what is possible in photonics technology. These developments are leading to more efficient, compact, and robust optical components that can be seamlessly integrated with electronic signals and systems. As photonics and electronics converge, the integration of photonic technology into electronic circuits is expected to play a transformative role in the development of future technologies, including the Internet of Things (IoT), 5G networks, and next-generation mobile devices.

Looking ahead, the continued evolution of precision optics and photonic integrated circuits will enable even more advanced applications, from high-resolution imaging and sensing to ultra-fast communication networks. As industries demand higher performance and greater efficiency, Elcon Precision will support manufacturing in photonics, and will remain a driving force behind technological progress, shaping the way we interact with the world and unlocking new possibilities for innovation.

Get in touch with our engineers, we’d love the opportunity to support your next project.