A decision guide from Elcon Precision for optimal metal brazing results, with decades of firsthand experience solving tough problems with precision solutions.

Brazing is a metal joining process that uses a filler metal, which is heated above its melting point and distributed between two or more close-fitting parts by capillary action. Unlike welding, the brazing process involves melting only the filler metal, not the base metals being joined. This allows different types of metals to be joined without compromising their structural integrity.

Brazing offers significant advantages over other joining methods, including increased speed, greater efficiency, and cost savings, making it ideal for high-productivity applications.

Breaking Down the Basic Fundamentals of Brazing

Brazing is a versatile metal joining process that involves joining two or more metal components by melting and flowing a filler metal into the joint. Unlike welding, the brazing process uses a filler metal with a lower melting point than the adjoining base metals, ensuring that the base metal itself does not melt. During brazing, the molten filler metal is drawn into the narrow gap between closely fitted parts by capillary action, creating a strong, sealed, and often leak-proof joint. This technique is widely used across industries such as medical, automotive, and aerospace due to its ability to join a variety of base metals, including steel, stainless steel, copper, and brass, without compromising their structural integrity. Silver brazing, in particular, is favored for its ability to join both ferrous and non-ferrous metals efficiently, making it ideal for applications requiring precision and reliability.

Achieving a high-quality brazed joint starts with proper joint design and meticulous preparation. Elcon's team of specialists know that a joint should be engineered to promote effective capillary action, allowing the molten filler metal to flow smoothly and fill the joint completely. Controlling the joint clearance, the gap between the two base metals, is critical.. Equally important is the cleanliness of the joint surface, as any contaminants such as oil, grease, or dirt can hinder the wetting and bonding of the filler metal.

Brazing Alloy Families Overview

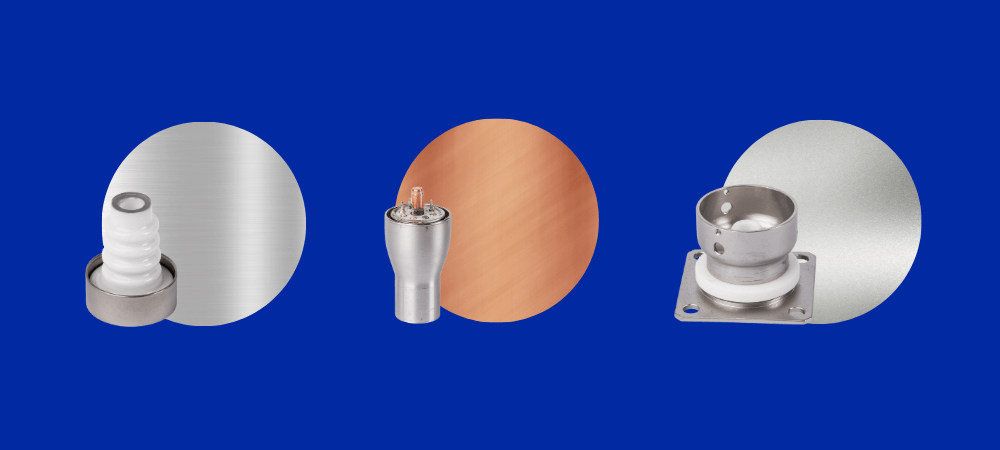

The choice of braze alloy directly impacts joint quality, process efficiency, and suitability for specific brazing work. Brazing alloys generally fall into three main families: silver brazing, copper brazing, and nickel brazing, each suited to specific performance needs, joint types, and alloy compatibility, including joining dissimilar base metals or when joining dissimilar metals that may require special consideration due to differences in thermal expansion.

- Silver Brazing Alloys – Excellent wettability, low melting temperatures, and broad compatibility with base metals. Silver brazed joints are known for their strong, leak-proof, and mechanically robust bonds, making them ideal for electronic assemblies, precision instruments, and components where heat distortion must be minimized.

- Copper Brazing Alloys – High conductivity, cost-effective, and strong in mechanical assemblies. Common in HVAC, heavy equipment, and electrical power components.

- Nickel Brazing Alloys – While Elcon primarily focuses on silver and copper brazing in our production work, our team has extensive knowledge of nickel brazing and its role in demanding environments. This expertise allows us to evaluate its advantages and guide customers toward the right alloy family for their application — even when nickel may not be the filler metal used in-house.

Brazing alloys are supplied in various forms, with brazing wires, filler metals in powders and pastes, and filler metal foils being common for different brazing work. These brazing alloys are selected based on properties such as brazing temperatures and melting temperatures, which are critical for ensuring proper joint formation and process reliability.

Common joint configurations for brazed assemblies include a lap joint and a butt joint. Lap joints and butt joints are commonly used in brazing, each offering specific advantages in terms of bonding area and load capacity.

Key Decision Criteria for Metal Brazing Alloys

When deciding between silver brazing, copper brazing, and nickel brazing, evaluate the following:

- Joint clearances are critical for achieving strong, leak-proof joints. Proper clearance is essential for optimal capillary action and filler metal distribution, which maximizes joint strength and reliability.

- The fit between adjoining metal surfaces and the cleanliness of the metal surface directly affect capillary action and joint quality.

- In joint design, control molten filler metal entering unwanted areas, such as blind holes, to prevent defects and flux entrapment.

- Consider the need for joint inspection to identify discontinuities and ensure joint integrity through nondestructive (NDT) examination.

- Cleanliness is crucial; it is important to remove flux residue and excess flux to prevent corrosion and joint failure.

- Process control should include careful management of the heating cycle and cooling cycles to maintain assembly alignment and joint quality.

- Evaluate different heating methods such as torch brazing, manual brazing, furnace brazing, and vacuum brazing. The use of a controlled atmosphere, including gases like hydrogen or nitrogen, can help prevent oxidation and may reduce or eliminate the need for flux.

Melt Range

Brazing filler metal plays a crucial role in filling the joint and forming a strong bond when it melts at the appropriate temperature.

- Lower melt ranges (common in silver brazing) reduce thermal stress and distortion, as the brazing filler metal melts at these temperatures, allowing for effective joint formation.

- Higher melt ranges (typical for nickel brazing) handle extreme heat environments.

Joint Strength

- Nickel brazing produces exceptional strength for high-temperature, high-stress joints.

- Silver and copper brazing alloys provide excellent strength for moderate temperature service. A silver brazed joint creates a strong, leak-proof, and corrosion-resistant connection, making it ideal for applications that require high mechanical strength and electrical conductivity.

Corrosion and Oxidation Resistance

- Nickel brazing offers superior oxidation and chemical resistance.

- Silver brazing resists corrosion but may tarnish.

- Copper brazing requires protective measures in corrosive environments.

Cost and Availability

- Silver brazing is generally the most expensive (precious metal content).

- Copper brazing is cost-friendly and widely available.

- Nickel brazing costs vary by specification and may have longer lead times.

A Quick Glance: Heating Methods

Selecting the right heating method is a critical step in the brazing process, as it directly affects the flow of the filler metal and the quality of the finished joint.

Where Elcon Precision shines is supporting high-volume production or applications requiring precise temperature control, furnace brazing is preferred. Furnace brazing uses a controlled atmosphere to heat the assembly evenly throughout the manufacturing process, minimizing oxidation and ensuring consistent results across each batch.

The choice of heating method depends on the type of filler metal, the base metals involved, and the specific quality requirements of the brazing operation.

Brazing Alloys Comparison Table

|

Criterion |

Silver Brazing |

Copper Brazing |

Nickel Brazing |

|---|---|---|---|

|

Melt Range (°C) |

~620–780 |

~1080–1085 |

~950–1200 |

|

Joint Strength |

High at low–mid temps |

High at mid temps |

Very high at high temps |

|

Corrosion Resistance |

Good, may tarnish |

Fair, needs protection |

Excellent |

|

Availability |

Widely available |

Readily available |

Specialty supply |

Application Examples for Silver, Copper, and Nickel Brazing

- Aerospace – Nickel brazing is widely used in turbine blades, exhaust systems, and structural components exposed to extreme heat and stress. Elcon’s expertise with nickel brazing ensures we understand these requirements, even if silver or copper alloys are ultimately the better fit for your project.

- Medical Devices – Silver brazing offers biocompatibility and precision joining for surgical tools, implants, and diagnostic equipment.

- Electronics – Low-melt silver brazing ensures delicate components are joined without heat damage.

- Heavy Equipment & Power Systems – Copper brazing is cost-effective and robust for electrical bus bars, motor components, and heat exchangers.

Joint Inspection and Quality Control -1

Throughout the brazing process, Elcon Precision continuously performs thorough inspections and maintains quality control throughout the manufacturing cycle. We believe this to be essential to ensure both the integrity and performance of the brazed joint, as well as promote continuous improvement, giving each of our team members opportunities to find innovative techniques to incorporate into future production runs. Visual inspection can reveal surface defects, but for critical applications, non-destructive testing methods such as radiography or ultrasonic testing are recommended to detect internal flaws like porosity or lack of fusion.

Consistent use of high-quality filler materials, adherence to correct brazing procedures, and regular maintenance of brazing equipment all contribute to Elcon's countless years of producing strong, reliable brazed joints that meet demanding industry standards.

Decision Framework for Metal Brazing Alloy Selection

- Identify operating conditions – service temperature, environment, and load.

- Match alloy performance – choose silver, copper, or nickel based on melt range, strength, and corrosion needs.

- Consider production efficiency – lower melt temperatures can speed up assembly and reduce warping.

- Balance performance with cost – factor in life cycle, reliability, and replacement rates, not just initial alloy price.

Still need to iron out the details? Contact Elcon Precision today to speak with a brazing specialist on selecting the ideal alloy and process for your next project.

The Elcon Precision Advantage in Brazing

With extensive expertise in brazing in all metals, and complex metal brazing assemblies, Elcon Precision delivers best-value solutions for OEMs in demanding industries. We stress the word value because high-quality work demands higher value and commitment to excellence.

Our metallurgical team evaluates your specific application, ensuring your brazed joints meet performance, cost, and reliability goals. Then, our brazing technicians perform high-temperature brazing for aerospace to precision brazing for microelectronics. We deliver consistent, high-quality results. All of which is backed by our rigorous quality program and unwavering pursuit of perfection.

Ready to optimize your brazing process? Request a Quote and one of our specialists will be in touch soon!