Built for the Demands of Modern Medicine

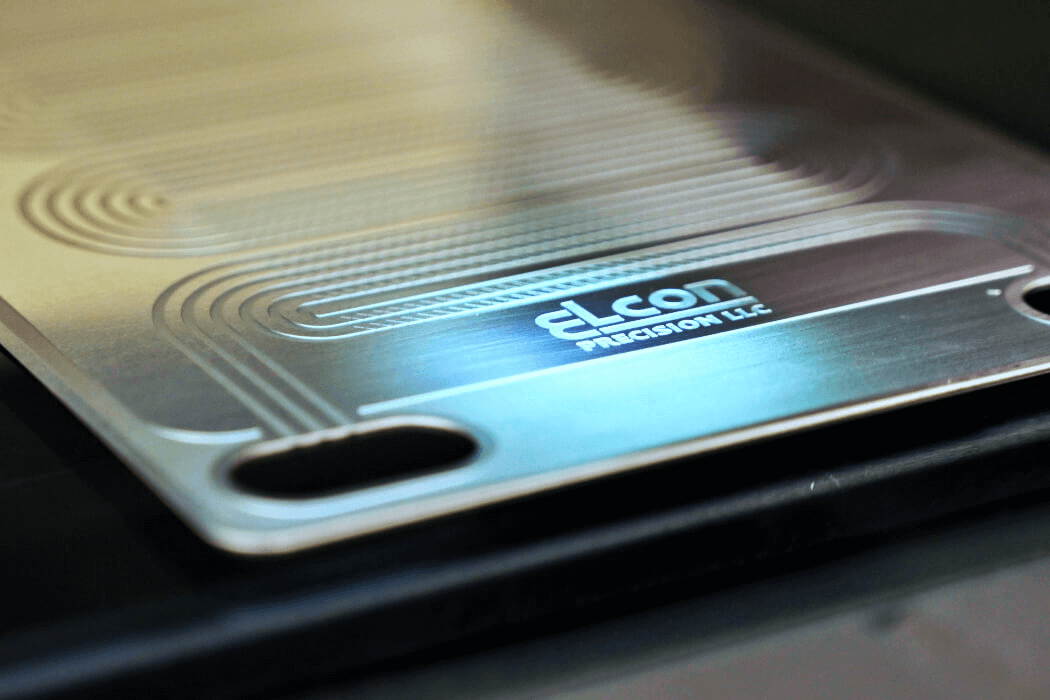

In the medical industry, precision isn’t just critical, it’s the difference between life or death. Every single component must meet precise quality standards for cleanliness, traceability, and biocompatibility. Equally as important, the technicians at Elcon processing the component or system, must also adhere to the same cleanliness practices you’d expect from your surgeon or nurse.

We understand what’s at stake, most importantly patient safety, long-term reliability, and clinical performance. It’s for this very reason that Elcon is continually engaged by top medical device manufacturers to tackle complex brazing applications.

What We Provide for the Medical Industry

Elcon specializes in advanced brazing and joining techniques to create robust, hermetically sealed components used in mission-critical healthcare devices. Our expertise includes, but is not limited to:

- Ceramic-to-metal and metal-to-metal brazed assemblies

- Hermetic sealing for implantable and diagnostic applications

- Material disciplines: alumina, sapphire, stainless steel, titanium, tungsten and zirconia ceramics

- •Custom designs for precision components in electro-medical systems

Whether you’re developing a next-generation neurostimulator or improving diagnostic imaging systems, Elcon is committed to helping bring your ideas to life, from initial prototyping to production-ready solutions.

Real World Applications for Real World Requirements

Elcon specializes in small- and high-volume manufacturing of highly precise components used in diagnostic and treatment applications throughout the medical industry, for both research and everyday uses. Through ceramic metallization, hermetic brazing, and photochemical machining, our services are used for components in oncology treatment and surgery applications, as pharmaceutical products and x-ray components in analytical instruments.

Implantable Medical Devices

Pacemakers, spinal implants, neurostimulators, and diagnostic wearables demand long-term reliability, and Elcon’s brazed assemblies meet these stringent requirements.

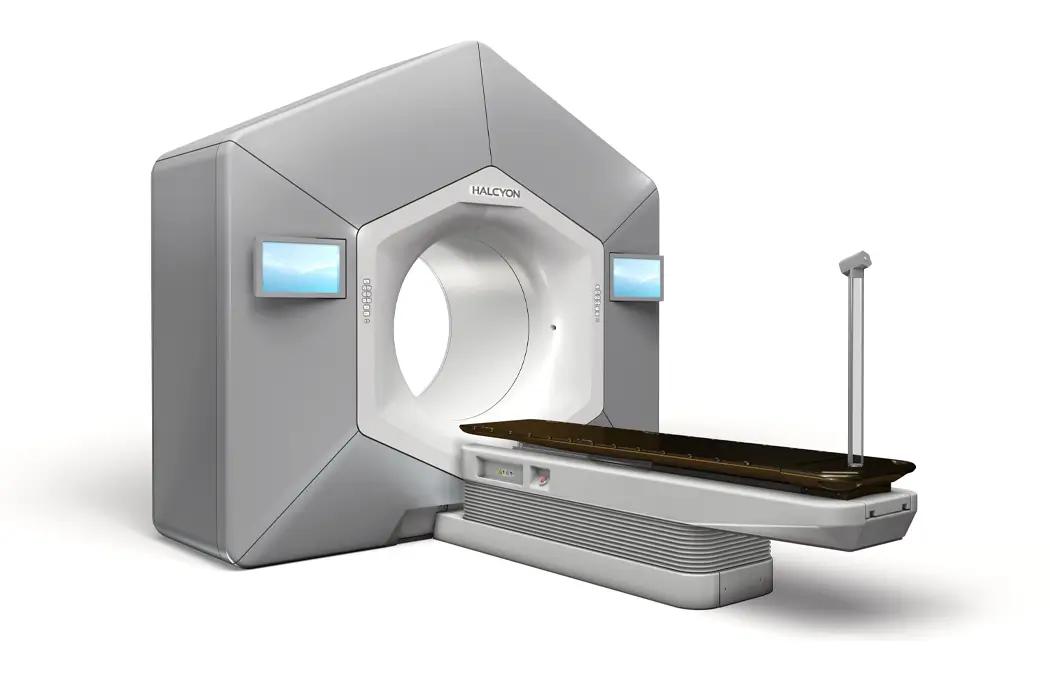

Diagnostic and Monitoring Equipment

Precision hermetic sealing protects sensors and electronic assemblies in diagnostic platforms such as medical atomizers, endoscopic sapphire windows, and electron guns for CT and MRI equipment.

Laser & Electro-Medical Housings

From light sources to cameras, Elcon supplies brazed housings that ensure component integrity under high-voltage, high-temperature, and vibration-prone environments.

Applications With Specific Materials

Ceramic Metallization and Brazed Assembly Applications

- X-ray assemblies

- Electron guns for CT and MRI machines

- Endoscopic sapphire windows

- Light sources and cameras

- Medical atomizers

- Diagnostic wearables

- Orthodontic devices

- Electrosurgical instruments

- Life science components

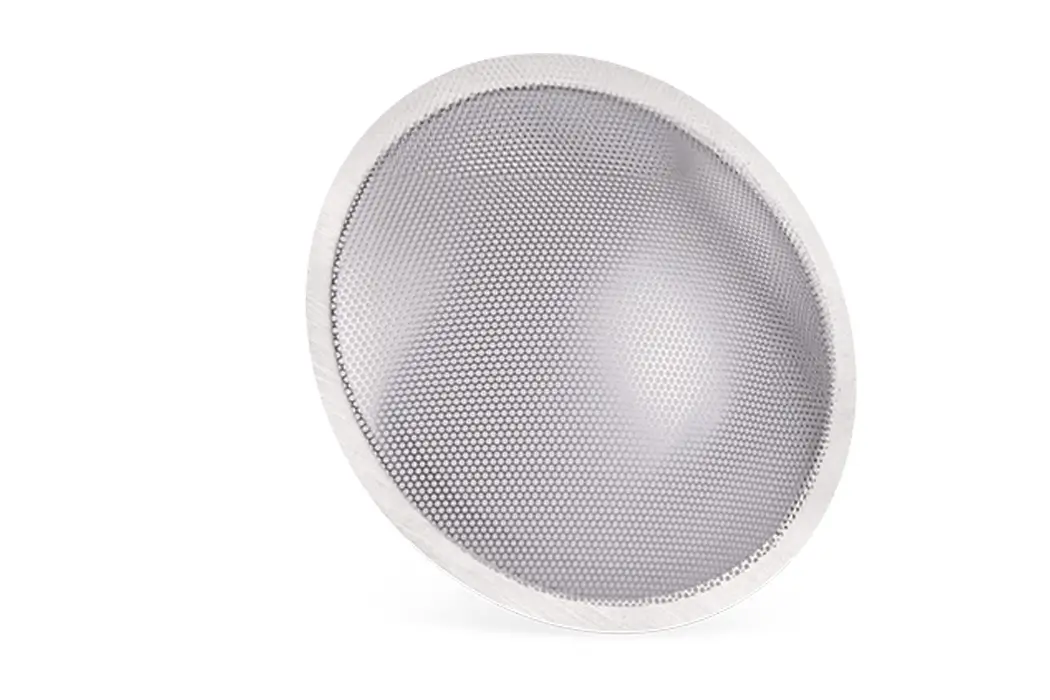

Photochemically Etched Metal Parts

- Arthroscopic surgery

- Titanium medical mesh & plates (e.g., cranial/maxillofacial implants)

- Shape memory implants

- Pharmaceutical powder screens for classification/filtration

- Disposable cutters

- Brain wave sensors

- Spinal implants

- Tungsten electrodes for tissue ablation

Compliance and Manufacturing Capabilities

We don’t just meet standards; we contribute to defining them for the medical industry as a whole. Our unwavering commitment to traceability and cleanliness ensures every component is delivered to spec, from a prototype ready for regulatory submission to a fully proven design that is ready for production ramp-up.

We’ve spent over 40 years building out the facilities, procuring the necessary equipment, cultivating experienced staff members, and maintaining quality certifications to ensure that your application conforms to each of the strict regulatory requirements. You’ve invested so much into your design to improve the medical industry, the last thing you need to worry about is your supplier mishandling the manufacturing process.

Quality Components at Elcon Precision:

- Full Traceability and Material Documentation (AS9100/ISO9001:2015 Certified)

- Support for Prototyping and Design for Manufacturability (DFM)

Why Medical OEMs Continually Choose Elcon

Deep Disciplinary Expertise

Decades of experience in medical, aerospace, and defense brazing, for extremely stringent programs and critical applications.

Custom Joint Design and Testing

Engineering collaboration from various departments to optimize brazed joints for performance and reliability, from testing to validating.

Scalable Production

From R&D prototyping and design iterations to high-volume production manufacturing with consistent quality from start to finish.

Trusted Innovation Partner

We strategically work directly with engineering and applications teams to solve complex design challenges based on real-time experience.

Let’s Build Something Life-Saving

On the cusp of something great? Whether you’re in early-stage development or ready for production, Elcon Precision is your trusted partner for high-reliability, medically compliant brazed assemblies. We are confident that with our deep understanding of the industry’s regulatory compliance, as well as our passion for providing best-in-class brazing services, we can bring your idea to reality.

Even more importantly, Elcon is here to build a partnership, and we are in it for the long haul, supporting your vision and lending our years of experience to improve the quality and viability of your application. We don’t just simply want to help build your product; we want to support the lifecycle of the program throughout its existence.

Reach out to Elcon today, and let’s improve your quality of life together, for tomorrow.