What Exactly Are Medical Linear Accelerators?

If you’ve ever wondered what linear accelerators are, they are highly specialized devices that use electromagnetic fields to accelerate charged particles to near-light speeds. A LINAC, short for linear accelerator, is a core technology in:

- Radiation therapy for cancer treatment

- Industrial non-destructive testing

- Scientific research and particle physics

- Cargo and vehicle inspection

Linear accelerators operate by generating an electric field and an accelerating field within a series of accelerating electrodes, powered by RF power and RF voltage. These electrical fields are established using voltage sources and accelerating voltage, creating accelerating gaps between drift tubes where charged particles gain energy. Sounds more complicated than it actually is, but the main point is that magnetic fields are used to focus and confine the accelerated particles as they move through the accelerator. Drift tubes shield particles from decelerating fields and help synchronize particle motion with the oscillating fields, with precision. In a linear accelerator, each particle passes through the accelerating structures only once, so the particle traverses a straight path, unlike in circular accelerators, where particles make multiple passes. As particle increases occur at each stage, the energy of the accelerated particles rises, with initial accelerators operating at a few MeV or up to a million volts. Some accelerators are designed for higher energy and higher beam current, utilizing traveling wave and standing wave techniques, as well as electromagnetic waves, to achieve efficient acceleration.

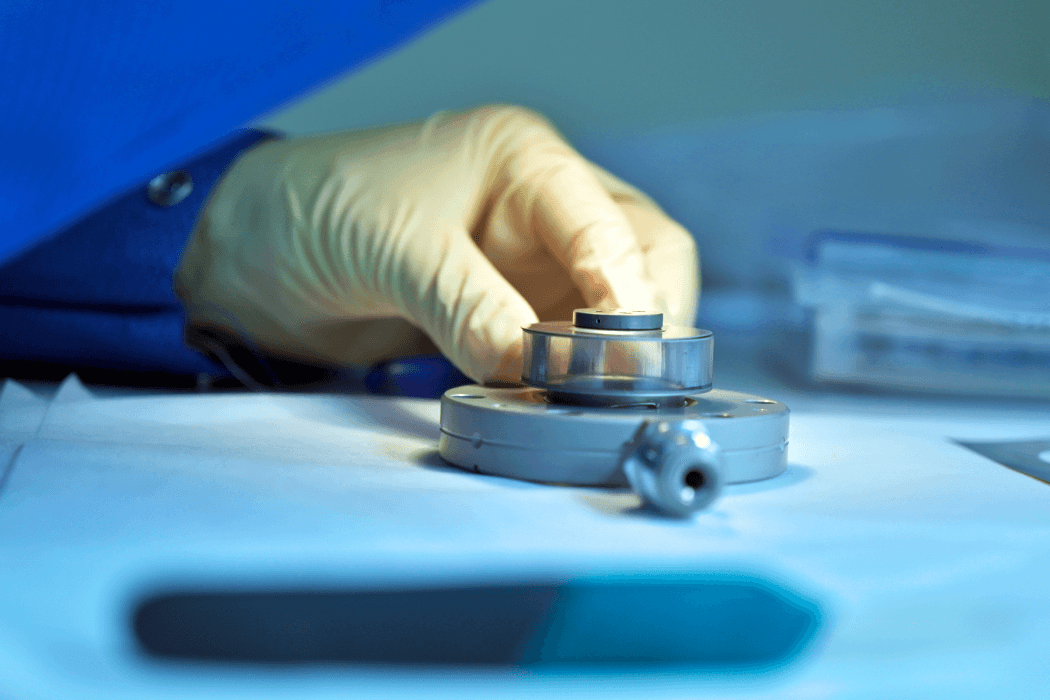

These systems require extreme accuracy, stability, and reliability to function. Every LINAC accelerator depends on precision-engineered components that can withstand high voltages, vacuum environments, and intense operational stress.

This is where Elcon Precision shines and provides a critical advantage.

Elcon’s Capabilities for LINAC & Linear Accelerator Components

For decades, Elcon Precision has supplied linear accelerators and LINAC accelerator OEMs with components and assemblies that meet stringent performance requirements. We specialize in:

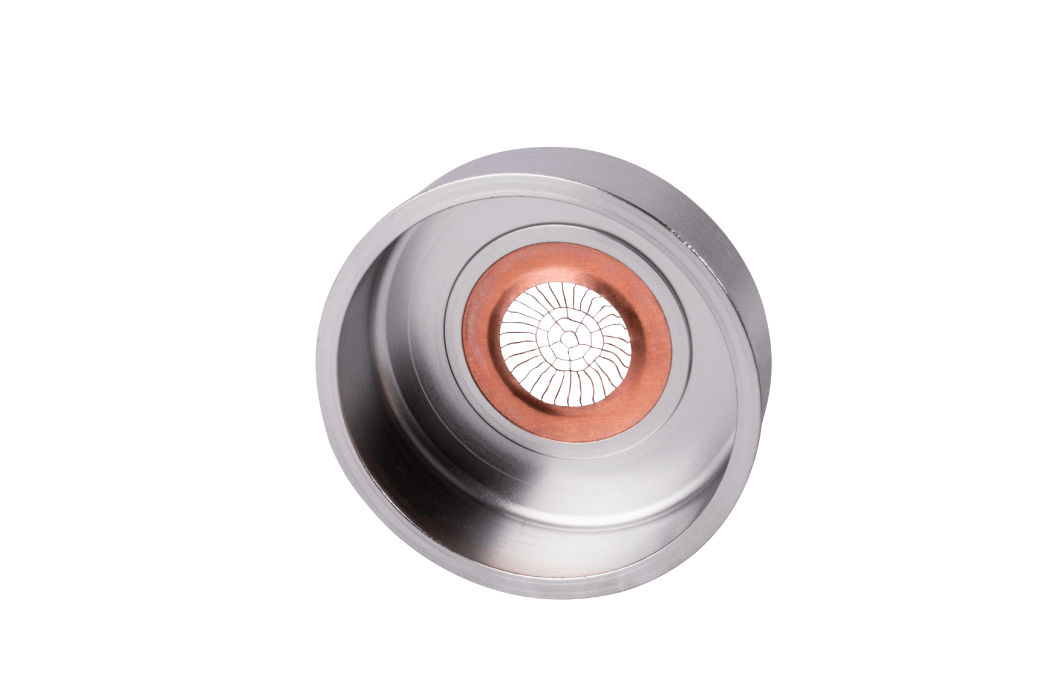

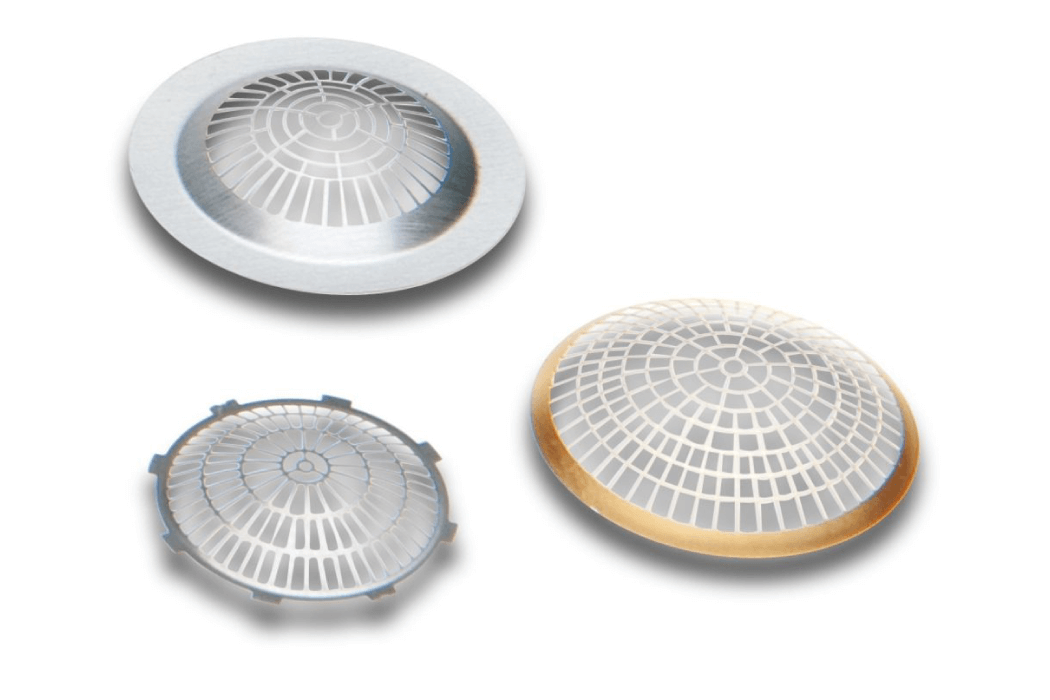

- Precision Brazing for High-Vacuum LINAC Assemblies – Ensuring strong, leak-free joints with alloys optimized for thermal and electrical performance.

- Ceramic-to-Metal Seals & Insulators for LINAC Linear Accelerators – Providing high-voltage isolation, exceptional dimensional control, and mechanical durability.

- Photochemically Etched Metal Parts – Perfect for LINAC subcomponents requiring complex geometries and tight tolerances.

- Advanced Material Expertise – Proficiency in high-temperature alloys, corrosion-resistant metals, and technical ceramics.

Performance Advantages for LINAC Systems in Cancer Treatment

Our manufacturing expertise ensures your LINAC linear accelerator parts deliver:

- Vacuum Integrity & Leak-Free Seals – Vital for maintaining optimal particle acceleration in the LINAC.

- High Electrical Insulation – Ceramic-to-metal seals prevent breakdown under extreme voltages.

- Mechanical Strength for High-Energy Environments – Built to endure repeated LINAC operational cycles.

- Repeatable Quality – Every linear accelerator component undergoes rigorous leak inspection and quality control.

Applications and Industries in Radiation Therapy

Elcon’s LINAC accelerator components are found in:

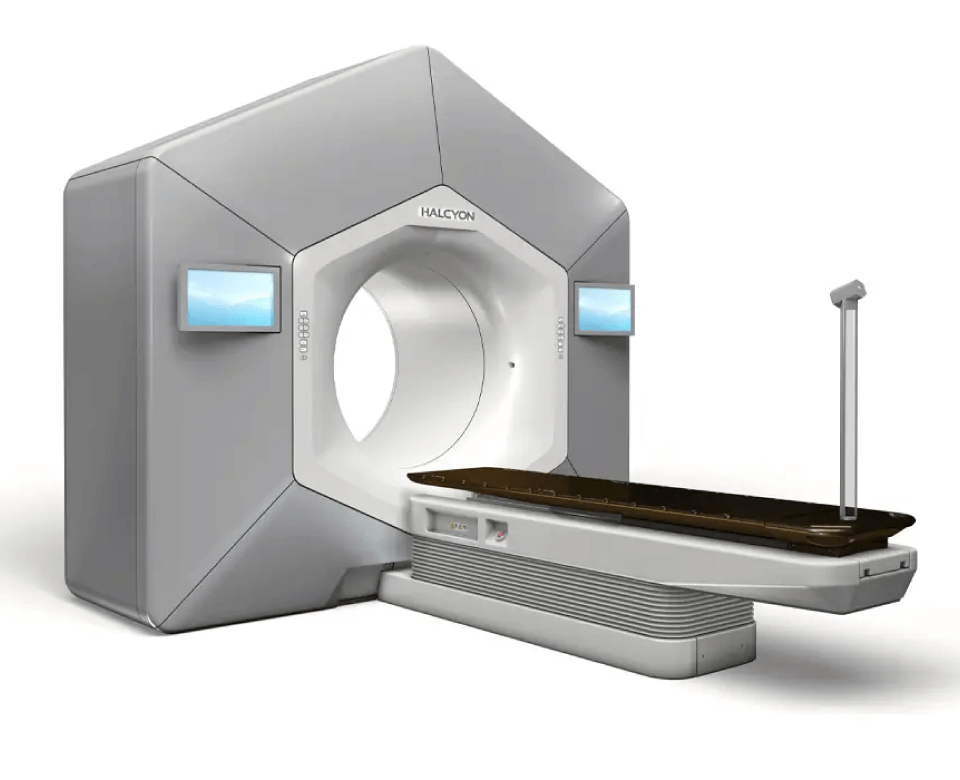

- Medical Radiation Therapy – Precision LINAC linear accelerators for oncology treatment centers worldwide. Medical linear accelerators are essential in radiation oncology, where they generate high-energy X-ray and gamma beams to deliver targeted treatments to the patient’s tumor.

- Industrial Non-Destructive Testing (NDT) – High-energy LINAC systems for materials inspection and structural evaluation.

- Scientific Particle Research – Linear accelerators used in nuclear physics, materials science, and advanced research facilities.

Quality and Compliance, No Exceptions

We know that every brazed LINAC component must perform flawlessly in mission-critical environments. That’s why we maintain:

- ISO-Certified Manufacturing – Ensuring consistency and full traceability.

- ITAR Compliance – Supporting U.S. defense-related LINAC applications.

- RoHS Compliance – Where applicable, for environmental safety.

Each linear accelerator component is verified for dimensional precision, material integrity, and seal performance before shipment.