Introduction to High Vacuum Technology

High vacuum technology underpins many of today’s most advanced scientific, industrial, and medical processes, where the ability to achieve and sustain ultra-high vacuum (UHV) and extreme high vacuum (XHV) environments is essential. These conditions demand precision, cleanliness, and long-term stability, making reliable vacuum components critical to system performance. Ion pumps are central to this technology: by using electric and magnetic fields to ionize residual gas molecules, then accelerating and trapping the resulting ions in solid electrodes, they create clean, stable, particle-free vacuums. Sputter ion pumps, in particular, enhance this process by efficiently removing gas molecules to maintain extreme vacuum levels over extended operation.

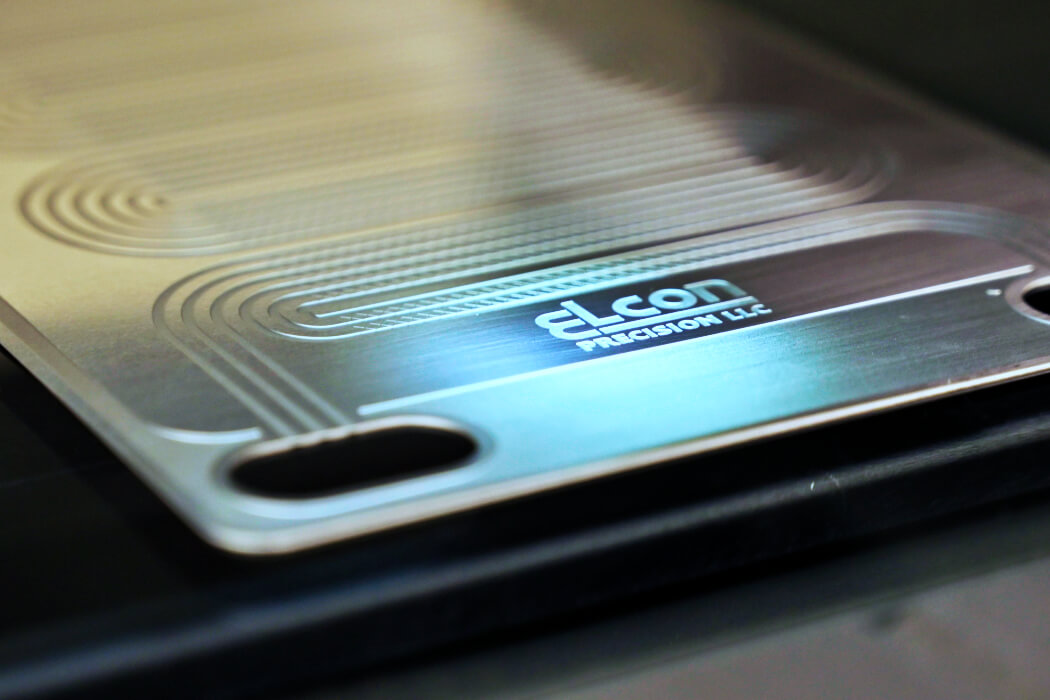

Supporting these systems, Elcon Precision manufactures the specialized components that make this performance possible. Our capabilities include ceramic-to-metal seals for hermetic integrity, photochemically etched grids for precise ion pump function, pump controllers for system management, coax feedthrough assemblies for secure connections, and engineered vacuum valves for dependable gas regulation. Notably, our all-metal valves provide robust metal-to-metal seals, making them ideal for demanding XHV applications where durability and integrity cannot be compromised.

By combining advanced ion pump technology with engineered vacuum components, Elcon ensures that vacuum systems operate with the precision and reliability required in high-tech industries such as semiconductor fabrication, scientific research, and medical diagnostics. This integration of performance-driven design and robust materials safeguards system integrity, enabling optimal results wherever vacuum technology plays a critical role.

Applications of Ion Pumps

Ion pumps and supporting vacuum technology are foundational across industries:

- Scientific Research

- Particle accelerators and synchrotrons

- Electron microscopes

- Surface science and advanced materials analysis

- Semiconductors

- Thin-film deposition

- Wafer fabrication

- Plasma processes requiring clean UHV systems, where preventing air ingress and using isolation valves is critical for maintaining system integrity.

- Medical & Industrial

- Mass spectrometers and X-ray imaging systems

- Analytical equipment for precision diagnostics

- Industrial vacuum valves supporting imaging and materials processing, with isolation valves ensuring air does not compromise sensitive environments.

- Aerospace & National Laboratories

- Space simulation chambers

- Advanced propulsion and satellite technology R&D

- Ultra-high vacuum systems supporting mission-critical experiments

Venting is essential for safe maintenance and effective pressure management in vacuum systems. Vacuum pumps are vital for maintaining vacuum conditions and preventing air contamination. Advanced vacuum applications require handling a wide range of pressures, including high differential pressures, to ensure optimal performance and safety.

Vacuum valves are available with pneumatic, manual, and pneumatically actuated options, providing precise control for various applications. Inline valves, with their axis parallel to the ports, are designed for smooth motion and optimized form to meet specific operational needs. Ball valves and other valves are produced under clean room conditions to achieve the high purity standards required in these industries.

Wherever ion pumps, vacuum valves, and coax feedthroughs are used, Elcon Precision delivers the quality and precision that long-term reliability demands.

Critical Considerations for Performance

The performance of a vacuum system depends heavily on the pumping speed and efficiency of its ion pumps. Pumping speed, the volume of gas removed from the chamber per unit of time, is a critical performance metric, influenced by factors such as the type of gas, system pressure, and cathode material. Sputter ion pumps are specifically engineered to deliver high pumping speeds for gases like hydrogen and noble gases, which are prevalent in high and ultra-high vacuum (UHV) environments. Their efficiency is further enhanced by strong magnetic fields and optimized electrode configurations, which improve ionization and gas capture. This design enables rapid gas removal with low power consumption and minimal maintenance, ensuring systems can reliably achieve and sustain UHV conditions.

Complementing ion pumps, vacuum valves are essential for regulating gas flow and isolating sections of the system. Gate valves, angle valves, and ball valves each offer advantages depending on the application, while flange types such as ConFlat (CF) flanges ensure compatibility and leak-tight performance in UHV systems. Beyond valves, the choice of additional vacuum pumps, ranging from roughing pumps like rotary vane or roots blowers to high-vacuum solutions such as oil diffusion pumps, plays a key role in system performance. These pumps are often staged in sequence, with roughing pumps handling initial evacuation and ion or diffusion pumps maintaining ultra-high vacuum levels.

Proper operation and maintenance are equally vital to sustaining ion pump performance over time. Ion pumps require a steady electrical supply, secure mounting, and adequate ventilation to prevent overheating during operation. Routine checks help preserve optimal pumping speed and efficiency, while maintenance tasks such as inspecting and replacing worn seals or cathodes, and cleaning pumps and valves to prevent contamination, safeguard the system’s integrity. By keeping all components in good working order, operators extend the life of the ion pump and reduce the risk of vacuum failures.

A high-performance vacuum system integrates advanced ion pump design, precision valve assemblies, staged pumping strategies, and proactive maintenance into a cohesive configuration. This attention to both engineering and upkeep ensures reliable operation, precise gas control, and long-term stability, enabling advanced research, manufacturing, and diagnostic applications to operate under the most demanding vacuum conditions.

Elcon’s Capabilities for Ion Pumps

Our manufacturing expertise ensures performance under the most demanding conditions:

- Ceramic-to-Metal Seals

- Provide unmatched vacuum integrity in UHV applications, with a reliable seal essential for maintaining vacuum performance

- Engineered for durability under high temperature and high voltage

- Photochemically Etched Grids & Electrodes

- Consistent tolerances for precise ionization

- Enhanced gas capture efficiency for extended pump life

- Getter materials can be activated by heating to regenerate the saturated getter surface, restoring their gas adsorption capability

- High-Voltage / High-Temperature Compatibility

- Built for coax feedthrough and ion pump systems that must operate under extreme environments, including compatibility with strong magnets used in these systems

- Custom Engineering

- Collaborative design support

- Prototype to production scalability for ion pumps, vacuum valves, and feedthrough assemblies

All components are manufactured under stringent clean room conditions, ensuring the highest levels of purity and consistency. At Elcon Precision, we maintain a controlled environment that eliminates contamination risks and supports the production of parts that meet exacting standards required for industries such as semiconductors, aerospace, medical devices, and defense.

Our ISO-certified quality management system integrates advanced inspection methods, precision measurement tools, and rigorous process controls at every stage of production. From incoming material verification to final inspection, every step is documented and traceable, guaranteeing repeatable performance and reliability.

With capabilities in tight-tolerance manufacturing, hermetic sealing, metallization, and complex ceramic-to-metal joining, Elcon delivers components that consistently exceed customer specifications. By combining clean room manufacturing with decades of engineering expertise, we provide solutions that ensure long-term durability, superior performance, and unmatched purity.

Why Elcon Precision

Elcon Precision is trusted by leaders in scientific research, semiconductor manufacturing, and aerospace engineering because we deliver:

Decades of Experience

In both ultra-high vacuum and vacuum electronics.

ISO-Certified Quality Management

Ensuring repeatable manufacturing processes without compromise.

Global Trust

Components chosen by national labs, medical innovators, and advanced manufacturers worldwide.

Our precision-engineered ion pump components, coax feedthroughs, and vacuum valve assemblies provide not just parts, but confidence in performance and longevity.